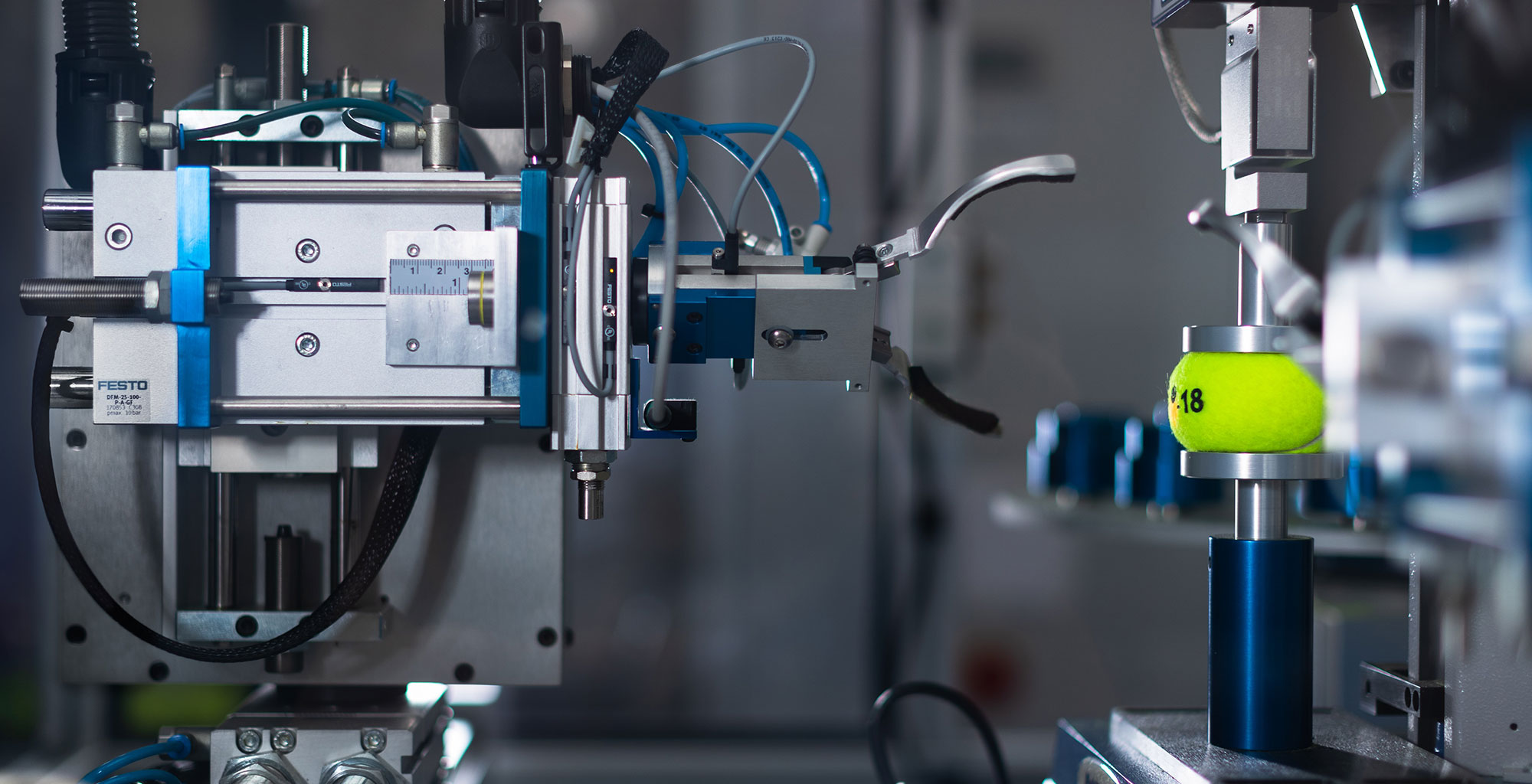

These companies typically operate multiple manufacturing plants, each with critical automated systems, such as assembly lines, industrial robots, SCADA (Supervisory Control and Data Acquisition) systems, and other IoT and OT (Operational Technology) devices. The purpose is to ensure that these industrial networks are protected against cyberattacks, minimizing the risk of production disruptions that could have a significant impact on operational efficiency and end-product quality.

Due to the pace of technological change and the need for specialized equipment, most organizations do not have the capacity to respond to today's sophisticated threats, leading to painful business processes, large ransomware payouts, legal expenses, reputational losses, etc.

In industrial environments, innovative applications and systems often coexist alongside equipment and operating systems that have been in the field for several years and will most likely need to remain in operation for several more years. These systems cannot always be updated, so it is necessary to establish protection mechanisms that make it impossible for cybercriminals to exploit vulnerabilities.

In this context, it is essential to design and implement a secure network architecture based on the segregation of IT and OT environments and the appropriate segregation of OT networks.

Hybrid Cloud

Hybrid Cloud Cyber Security & NaaS

Cyber Security & NaaS AI & Data

AI & Data IoT & Connectivity

IoT & Connectivity Business Applications

Business Applications Intelligent Workplace

Intelligent Workplace Consulting & Professional Services

Consulting & Professional Services Small Medium Enterprise

Small Medium Enterprise Health and Social Care

Health and Social Care Industry

Industry Retail

Retail Tourism and Leisure

Tourism and Leisure Transport & Logistics

Transport & Logistics Energy & Utilities

Energy & Utilities Banking and Finance

Banking and Finance Smart Cities

Smart Cities Public Sector

Public Sector