Real time asset tracking thanks to accurate and efficient UWB connectivity

As the industrial sector evolved over the years, it integrated technology to face constant challenges and improve its competitiveness, thereby consolidating itself in the Industry 4.0 era.

In this process of digitalization and transformation, several technologies facilitate the advancement and adaptation to new industrial challenges. Among them, the IoT (Internet of Things) solution for asset tracking and monitoring stands out. This activity leads to a substantial improvement in the safety and efficiency of processes. However, the deployment of this infrastructure also presents challenges that must be addressed.

What technology is needed to implement this solution? What level of accuracy is required for the service to be optimal? Which assets should be monitored and how often?

Real Time Location Systems (RTLS)

Real Time Location Systems (RTLS) provide answers to these questions.

These systems are characterized by the precise and continuous location of assets or people in real time within a defined area using advanced technologies such as UWB connectivity (Ultra Wide Band).

What is Ultra Wide Band (UWB)?

Ultra Wide Band is a wireless communication technology that uses a wide frequency spectrum to transmit data at high speeds and with sub-meter accuracy, less than one meter.

✅ This capability makes it ideal for applications requiring precise location and efficient data transmission.

How does UWB work?

UWB connectivity operates by emitting short-duration radio frequency pulses in a broad spectrum.

✅ Unlike other wireless technologies, UWB is not affected by signal interference or metallic environments and provides centimeter-accurate location.

What differentiates UWB from other technologies?

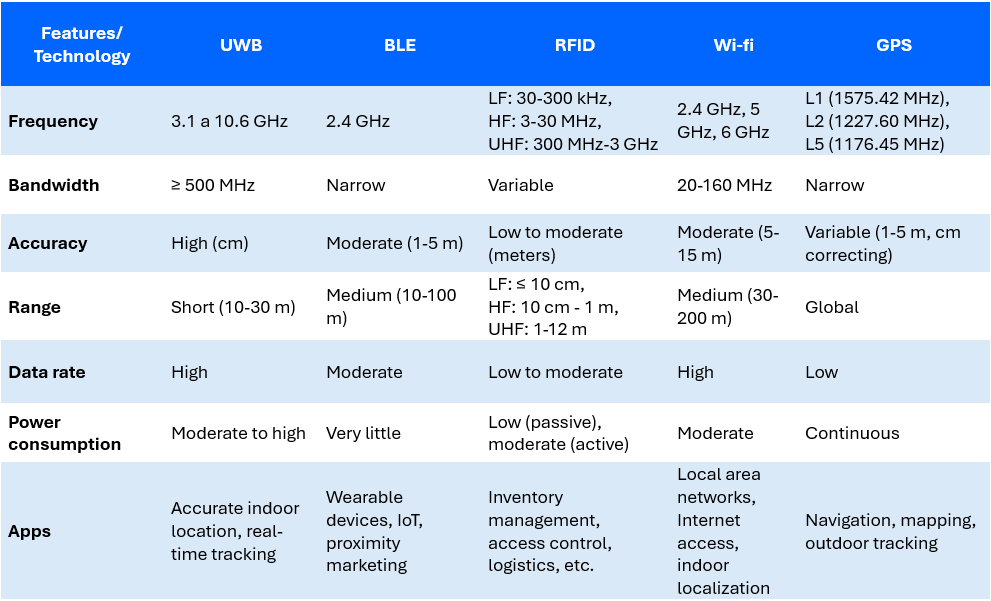

Ultra Wide Band, as well as BLE (Bluetooth Low Energy), RFID (Radio Frequency Identification), GPS (Global Positioning System) and Wi-fi, are popular technologies for tracking and wireless communication. However, they have significant differences in terms of their features, applications and performance.

UWB differs from the rest by its extreme accuracy, low interference and high data rate.

—The table below defines the differences between the aforementioned technologies:

Implementing RTLS with UWB Wireless Technology

Putting theory into practice, here is an example of how an RTLS can be implemented with Ultra Wide Band.

Elements:

- Installation of UWB antennas in fixed positions along the production plant. These anchors serve as reference points to calculate the position of the tags (depending on the characteristics and needs of the customer varies).

- UWB tags are placed on critical assets that need to be tracked. These tags emit UWB signals that are picked up by the installed anchors.

- The software system receives the signals from the tags through the antennas and calculates the exact position of each tag. This software can be integrated with the plant's Production Management System (MES) for real-time monitoring.

Practical example in the production process

- Receipt and storage of components: When key components arrive at the plant, they are assigned UWB tags. As they are stored the RTLS system automatically records their exact location in the warehouse.

- Component movement to the assembly area: When a component is required on the assembly line the RTLS system tracks its movement from the warehouse to the corresponding workstation. If a component deviates from the planned route the system alerts personnel.

- Track vehicle progress: Vehicles on the assembly line also have UWB tags. As the vehicle progresses through the various workstations the RTLS system records its progress in real time, allowing accurate monitoring of the workflow.

- Finished vehicle exit: At the end of assembly the vehicle moves to the final inspection area, with the RTLS system recording its exit from the assembly line and its entry into the inspection area. Finally, when the vehicle is approved and leaves the plant for distribution, its last location is recorded in the system.

Conclusion

Asset tracking with the implementation of RTLS and UWB technology marks a milestone in the evolution of Industry 4.0. This advancement not only enables accurate, real-time location, but also optimizes the efficiency and safety of industrial processes.

Companies can overcome the traditional challenges of asset tracking by integrating systems such as IoT and UWB, achieving more effective management and informed decision making.

UWB's ability to provide sub-meter accuracy, even in complex environments, differentiates it from other technologies such as BLE, RFID, Wi-Fi and GPS, making RTLS an indispensable tool for modern industry.

The practical implementation of these solutions, from the receipt of components to the output of the finished product, shows how technology can completely transform industrial operations.

____

Hybrid Cloud

Hybrid Cloud Cyber Security & NaaS

Cyber Security & NaaS AI & Data

AI & Data IoT & Connectivity

IoT & Connectivity Business Applications

Business Applications Intelligent Workplace

Intelligent Workplace Consulting & Professional Services

Consulting & Professional Services Small Medium Enterprise

Small Medium Enterprise Health and Social Care

Health and Social Care Industry

Industry Retail

Retail Tourism and Leisure

Tourism and Leisure Transport & Logistics

Transport & Logistics Energy & Utilities

Energy & Utilities Banking and Finance

Banking and Finance Smart Cities

Smart Cities Public Sector

Public Sector