Scada System: What is and its benefits in Industry 4.0

What is a SCADA System?

A SCADA system is a software and hardware solution designed to monitor, control, and collect real-time data from industrial processes. These systems are composed of a number of components, including sensors, controllers, data acquisition devices and a user interface that allows operators to monitor and manage processes from a centralized location.

The architecture of a SCADA system consists of several layers, including the field layer, where the sensors and actuators are located, the control layer, which is responsible for processing the information and acting on the plant itself, and the supervisory layer, which provides a graphical interface for operators to monitor and control the processes.

SCADA supervises and manages industrial processes in real time, integrating hardware and software for efficient centralized monitoring.

We place it in the middle layer within the classic automation pyramid, as it is a key tool that allows data to be extracted from the lower layers and exploited with software found in the upper layers such as MOM systems and ERP.

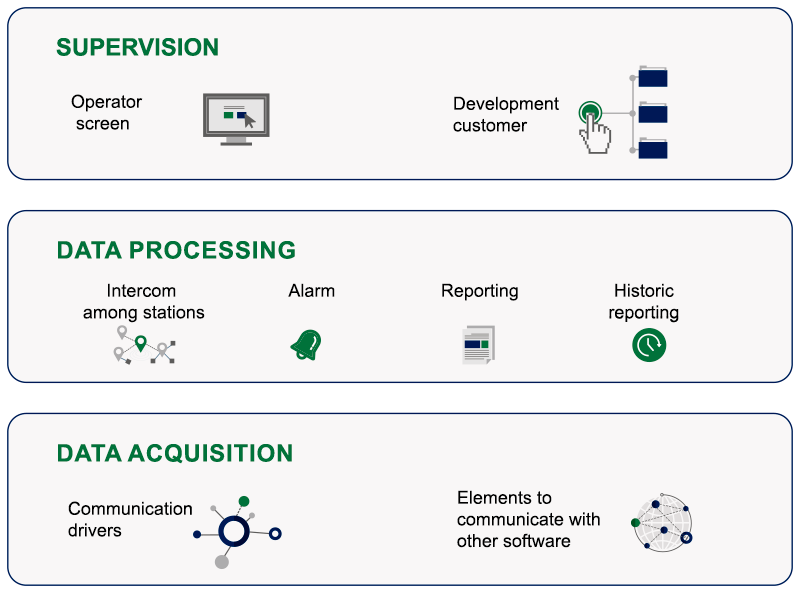

The following is a detailed breakdown of the three main layers of a Scada system:

- Supervisory: This part of the system involves the visualization and supervision of process data in a user-friendly interface. Operators can monitor equipment status, process conditions and other important parameters.

- Control: Scada allows operators to control industrial processes by issuing commands through the user interface. This can include parameter adjustments, equipment activation or deactivation, and other actions necessary to keep the process running optimally.

- Data Acquisition: This function involves the collection of real-time data from sensors and other devices connected to the system. This data is then processed and presented on the user interface for monitoring and analysis.

The implementation of a SCADA (Supervisory Control and Data Acquisition) system plays a key role in the digital transformation of a production plant by providing a comprehensive technology platform to monitor, control and optimize production processes.

Here are some key points in which a SCADA contributes to this transformation:

Data centralization

SCADA centralizes the collection of data from different devices and systems throughout the plant.

✅ This provides a unified view of production data and facilitates access to critical information from a single user interface.

Real-time monitoring

SCADA enables real-time monitoring of all aspects of plant operation, including production levels, product quality and environmental conditions.

✅ Operators can quickly detect and respond to any anomalies or problems, minimizing downtime and helping to maximize operational efficiency.

Remote control

The remote control capability of SCADA allows operators to monitor and control production processes from any location, including via mobile devices thanks to the web environment provided by many of the software manufacturers.

✅ This provides greater flexibility and responsiveness, especially in emergency situations or when quick adjustments need to be made to the production line.

Process Automation

SCADA facilitates process automation by enabling task scheduling and script execution.

✅ This reduces dependence on human intervention at night, for example, and improves accuracy and consistency in the execution of repetitive tasks.

Efficiency optimization

SCADA provides valuable information on plant performance and individual processes by collecting and analyzing data in real time. Monitoring line availability is necessary to ensure the highest possible efficiency in each process.

✅ This makes it possible to identify areas for improvement and optimize processes to maximize productivity.

System integration

SCADA facilitates the integration of heterogeneous systems and devices throughout the plant, including PLCs, sensors, energy management systems, and quality management systems.

✅ This creates a connected ecosystem where data can flow freely between different layers, facilitating informed decision making and optimization of plant operations.

Regulatory compliance and reporting

SCADA provides a detailed record of process data such as variables and environmental parameters involved in production, facilitating compliance with regulations and industry standards.

Reports generated by SCADA can be used to document compliance and respond to internal and external audit requests efficiently.

Conclusion

SCADA systems play a critical role in the digital transformation of a production plant by providing a comprehensive technology platform for monitoring, control, and data acquisition of production processes.

This allows us to create a very stable ecosystem for scaling up to the business layer with other indispensable tools such as MES, GMAP, APS, etc. In this way we can improve the operational efficiency, productivity, and competitiveness of the plant in today's market.

Image by ArtPhoto_studio at Freepik.

Hybrid Cloud

Hybrid Cloud Cyber Security & NaaS

Cyber Security & NaaS AI & Data

AI & Data IoT & Connectivity

IoT & Connectivity Business Applications

Business Applications Intelligent Workplace

Intelligent Workplace Consulting & Professional Services

Consulting & Professional Services Small Medium Enterprise

Small Medium Enterprise Health and Social Care

Health and Social Care Industry

Industry Retail

Retail Tourism and Leisure

Tourism and Leisure Transport & Logistics

Transport & Logistics Energy & Utilities

Energy & Utilities Banking and Finance

Banking and Finance Smart Cities

Smart Cities Public Sector

Public Sector